Research in close collaboration between AD Chemicals and Compri Coating Service demonstrates that business owners should not be afraid of filiform corrosion. Furthermore, on recycled aluminium, a high quality level pre-treatment and powder coating process can be realized that meets the Qualicoat standards.

Essential for responding to this market development is overseeing the impact on the entire chain; from design till end of life of a coated object. To give insight, first we explain what filiform corrosion is, the impact of recycled aluminium followed by testing methods of filiform corrosion. In the final section, there will be further elaborated on product innovation, which will allow the reader to think about different approaches to pre-treatment in the future.

What is filiform corrosion?

According to VOM and Association ION the definition is as follows: “Filiform corrosion is a filamentous form of corrosion which mainly occurs on coated aluminium. The phenomenon begins from areas where no, or insufficient, coating is applied. Some examples include saw edges, cutting holes, damages, and sharp edges with insufficient edge coverage. By carrying out the processing steps with high accuracy, makes it possible to reduce the risk of filiform corrosion to a minimum. ”According to Sciencedirect, the scientific definition is: “The filament progresses from the cathodic site, which is the source of the oxygen to the anode, which is the head and where the surface dissolution of aluminium and the formation of corrosion products Al(OH)3 take place. The main parameters governing filiform corrosion are: alloy compositions, scalping of ingots and billets, heat treatments, condition of the metal surface layer, relative humidity (RH), temperature, grinding, etching and preliminary surface treatments.”

Ludo Appels (Director Compri Coating Service) has inventoried cases of damage of the past 25 years and concluded that corrosion always develops from “uncoated” areas: Cutting edges, mitered corners, waterholes, sharp edges, and drilling holes. In all his years in the field he has never seen filiform corrosion occur from the centre of a profile or plate. Furthermore, filiform corrosion is more often found on extrusion alloy than on plate alloy (See Image 1: Examples of filiform corrosion (Source: Website Comham Holland, 2023)). In addition, it is important for architects to take possible sources of corrosion into account when designing constructions. According to Ludo Appels, a good example is a project for balcony fences where horizontal handrail was mounted to a vertical balustrade of aluminium. Corrosion originated from the vertical parts, whereas everything was identically coated on the same day. The root cause could be found at the edges, which were not angled, and the rails was mounted in a moulding with unsealed screws. All of this together in a C5 corrosion environment close to the coastal line, contributes to corrosion (Image 2: Examples of construction designs with an increased corrosion risk).

Image 1: Examples of filiform corrosion (Source: Website Comham Holland, 2023)

Increased recycled aluminium

Every business owner in Europe faces the same challenge: An increasing amount of recycled aluminium enters the European market as a result of additional focus on durability, circular economy, ecological footprint, etc. Characteristic to this type of aluminium compared to primary aluminium is that it often contains up to five times higher Zinc (Zn) and copper (Cu) values, while still adhering to the alloy standard (Table 1: Example of alloy elements recycled aluminium versus primary aluminium.)

Since the introduction of recycled aluminium, an increase in failed corrosion tests (salt spray test and FFC test) has been observed at inspection laboratories (e.g. Qualicoat inspections.). It should be noted that this statement does not apply to all producers of recycled aluminum. In some instances, the performance of recycled aluminum is nearly identical to that of primary aluminum.

Table 1: Example of alloy elements recycled aluminium versus primary aluminium

The chemical pre-treatment of aluminium, according to “seaside” specifications, is originally based on the fact that deeper etching (>2g/m²) would remove the interfering alloy elements like copper and zinc or at least bring these to an acceptable level for pre-treatment. This should improve corrosion resistance. AD Chemicals and Compri Coating decided to test if this procedure, used already for many years on primary aluminium, would lead to acceptable quality on recycled aluminium. The test trajectory was based on the following principles:

- Primary and recycled aluminium identically pre-treated with the same bath parameters, concentrations, treatment schedule, and temperatures.

- Both samples with the same etch rate (Seaside pre-treatment >2g/m²).

- Both samples handled in the same oven according to curing standards of the powder coating manufacturer.

- All samples tested in the same salt spray cabinet.

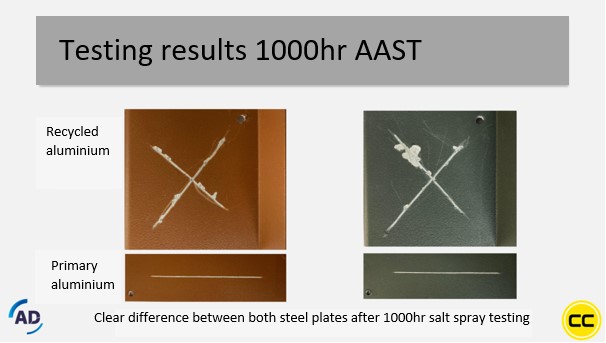

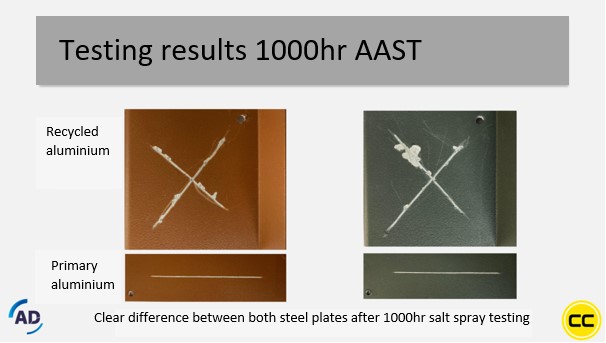

Image 3 displays the results after a 1000 hours in a salt spray test (AAST), which clearly demonstrates a lower corrosion protection for recycled aluminium. This research shows that it is not only the concentration of Copper and Zinc that is decisive, but rather also the proportion towards each other. When these two elements are present in a ratio of 1:1 in an alloy, the corrosion resistance remains excellent.

In current scientific literature similar results are reported; when different alloy compositions are used, the results of the salt spray test becomes significantly less.

Image 3: Testing results 1000hr AAST